Send us a message

We would like to learn more about your challenges and to understand how we can support you.

Agriculture, Hazardous chemicals

Virtual Reality

Virtual reality simulation for training of handling hazardous materials and transferring ammonia in a hazardous environment

CLIENT

Nutrien Ag Solutions

OBJECTIVE

Create a digital twin for hands-on training required to safely transfer ammonia from a transport vehicle to a storage vessel.

APPROACH

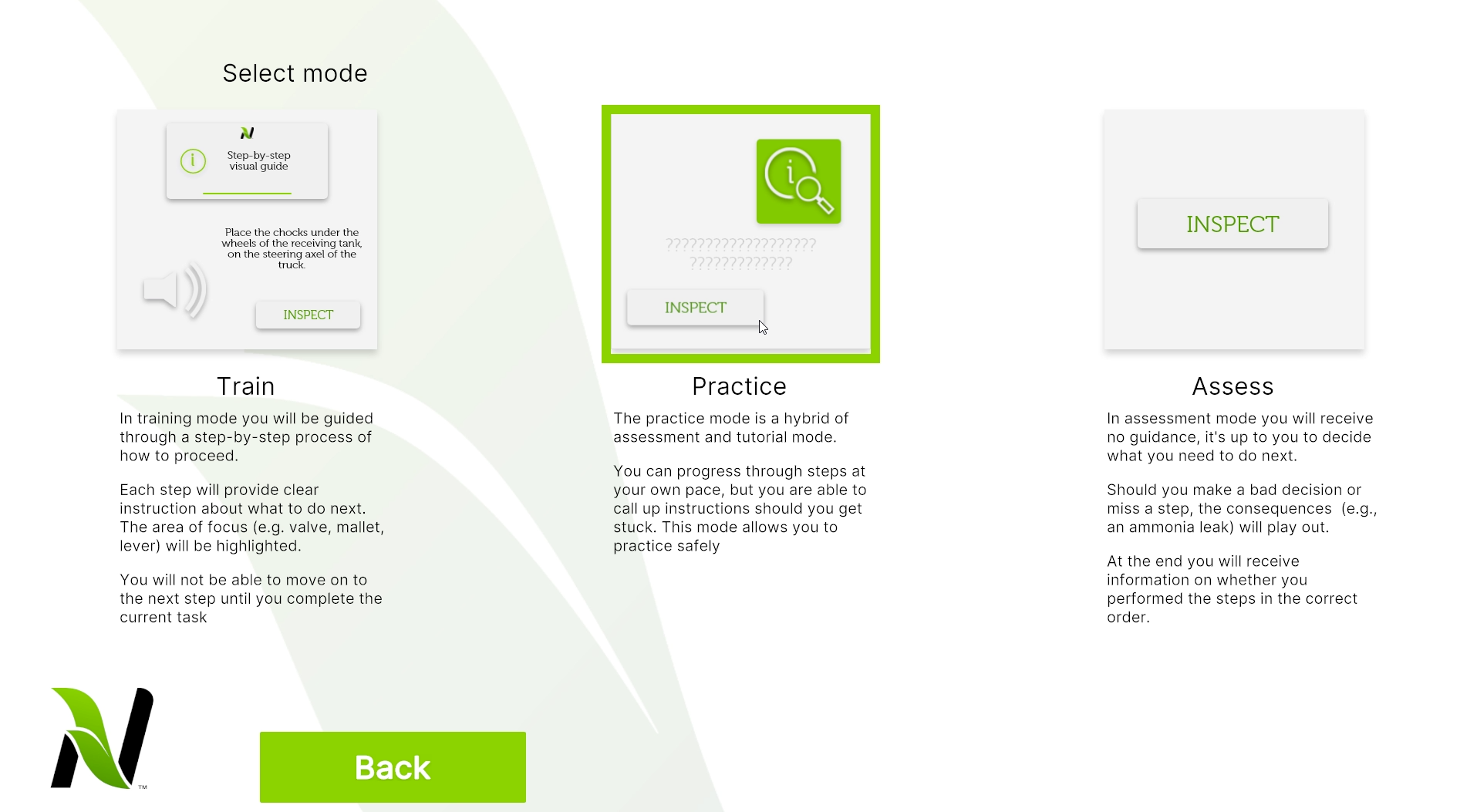

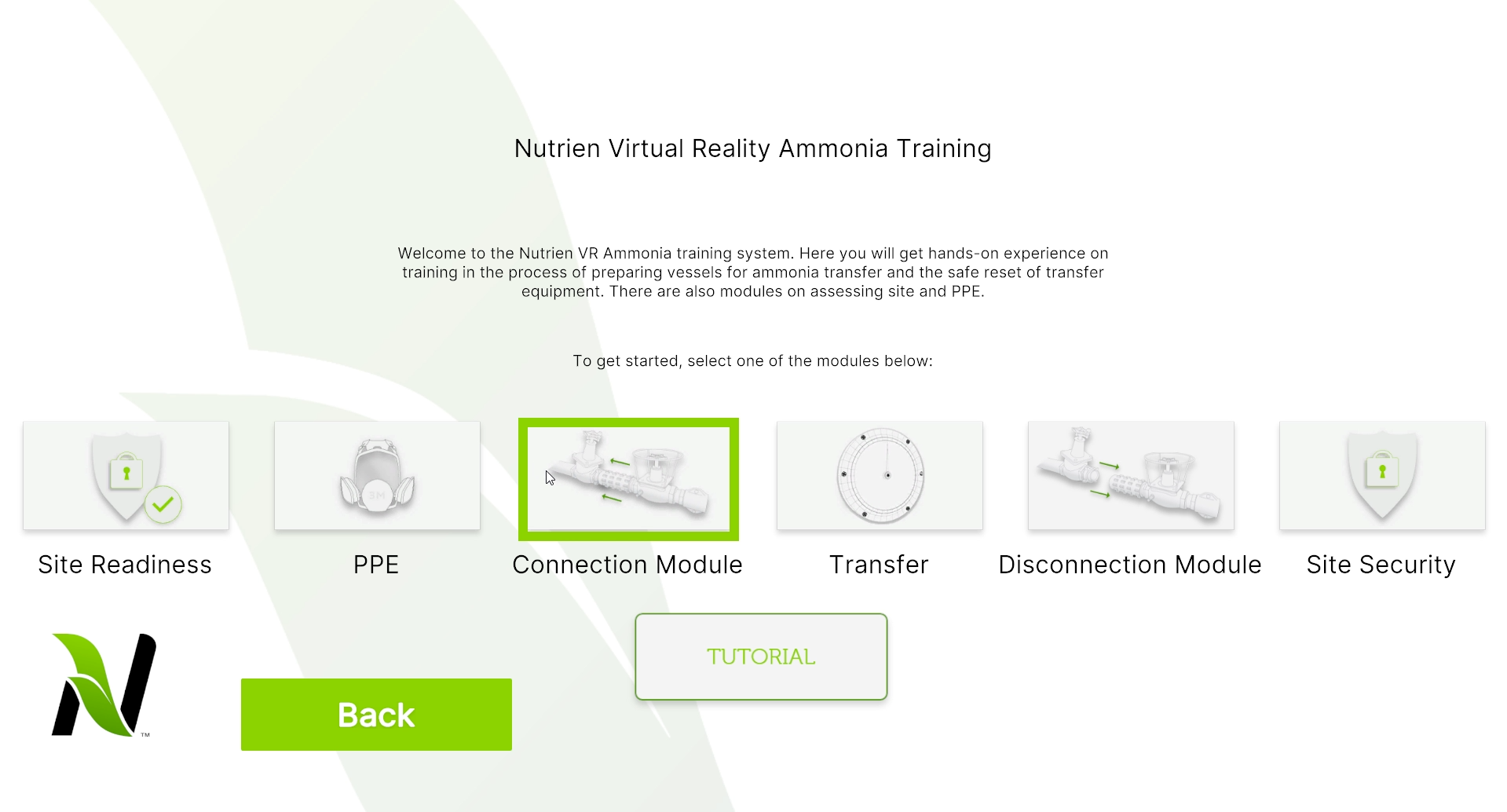

Nutrien’s complex process of transferring the hazardous ammonia safely consists of 60+ steps. We needed our solution to function as an exact virtual replica of Nutrien’s real site, so we created a digital twin of their site in which users can fully interact with all pipes, valves, buttons, etc. exactly as they would in real life.

The Nutrien Ammonia transfer is a complex and highly specific procedure involving over 60 steps from the putting on the correct PPE, preparing the site, connecting equipment, transfer, disconnection, correctly exiting the site, etc. Almost all these steps require precision and adherence to strict safety protocols.

The process is not only difficult to memorize due to its length and complexity, but any deviation from the standard procedure can have severe consequences. Ammonia is a dangerous chemical that poses significant risks to both the environment and human health, meaning even a small mistake, such as incorrect valve operation or mismanagement of pressure systems, can lead to hazardous leaks, chemical burns, or even catastrophic explosions. This complexity makes traditional training methods insufficient, as they rely heavily on memorization, leaving room for human error in high-stress, real-world situations.

Nutrien needed a solution to reduce the odds of a safety hazard and to keep their engineers and our environment safe, they needed to train engineers without placing them into a highly dangerous environment, and without the need of incredibly expensive physical dummy equipment. But how can they learn to use equipment and complete the lengthy physical process without being able to train with the actual equipment?

Virtual reality for high risk training is an incredible way to mitigate risks in hazardous environments and eliminate the dangers inexperienced employees may face when training for a new role. Shiift decided to harness the amazing power of virtual reality and created a digital twin of their site and equipment, where users could enter the site and interact with every inch of it within a VR headset or via the web application.

Instantly, thousands of users can access the digital twin at once and complete the full 60+ step process as many times as they need to without any additional cost after initial deployment. VR users can train their muscle memory with the physical equipment, and do the same process on Nutrien’s LMS with mouse and keyboard controls if they prefer. The system tracks all user’s interactions with equipment and submits data to Nutrien’s LMS directly so that users may be assessed on how they understand the process.

PROJECTS YOU MIGHT BE INTERESTED IN

Get in touch.

Send us a message and we’ll get

back to you within 48 hours.

Alternatively, email

hello@shiifttraining.com

Deliver next generation training. Get in touch.

Email us at hello@shiifttraining.com or send

us a message and we’ll be in touch within 48hrs.