Introduction

Modern manufacturing environments are complex, high-pressure, and risk-laden. Operators handle powerful machinery, hazardous chemicals, and intricate workflows where a single misstep can cause injury, downtime, or costly errors. Traditional on-the-job training often requires real equipment, creating unavoidable exposure to risk during the learning phase.

Hands-on experience remains essential for mastering procedures and building confidence. Yet, when safety and productivity are on the line, how do organizations provide realistic practice without jeopardizing people or operations?

Virtual reality (VR) offers an answer. By merging realistic 3D simulations with interactive learning, VR provides a repeatable, measurable, and immersive environment where workers can safely train for complex tasks and hazardous situations. The technology not only enhances industrial safety but also accelerates skill acquisition, setting a new benchmark for manufacturing training.

Evidence supporting VR Training’s benefits in manufacturing

The leading manufacturing industries like Ford, General Electronics, Daikin Global, or Lockheed Martin have successfully incorporated VR/AR technology in their workforce training. Lockheed Martin used analytics to compare the results of their standard training against the VR training. Lockheed Martin reported that workers that received VR training worked faster, with a 96% accuracy during real-world fabrication.

Evidence like this and the continued adoption from these major companies investing in VR training whether through SHIIFT or another provider make it clear that VR training will continue to grow in the manufacturing sector, and will become the standard in the future for improving both safety and productivity.

Challenges of Traditional Manufacturing Training

Manufacturing training has long relied on shadowing, classroom sessions, and limited practice runs for workforce training. However, these methods face several persistent challenges:

- High risk of injury when trainees handle heavy machinery or chemicals without mastery of safety procedures.

- Costly downtime when production equipment must be taken offline for instructional use.

- Inconsistent training quality, especially across shifts or locations where instructor style and available resources vary.

- Limited exposure to rare scenarios, such as chemical spills or mechanical failures, which are difficult or unsafe to recreate for practice.

These constraints make it difficult to ensure uniform safety standards or true readiness among the workforce.

How VR Training Solves These Challenges

Virtual Reality (VR) overcomes these traditional barriers through simulation and immersion.

- Trainees can experience hazardous scenarios safely, such as fires, high-voltage maintenance, or lockout tagout exercises.

- Immersive visuals and motion-based interactions enhance muscle memory, situational awareness, and decision-making under pressure.

- Standardized digital training modules ensure consistent instruction across multiple plants or global facilities.

- Complex or rarely encountered situations can be repeated until mastery, eliminating the one-time limitation of live training.

By recreating real-world conditions with zero risk, VR empowers workers to make mistakes, learn from them, and gain confidence, all in a controlled environment.

15 VR Training Use Cases in Manufacturing Training

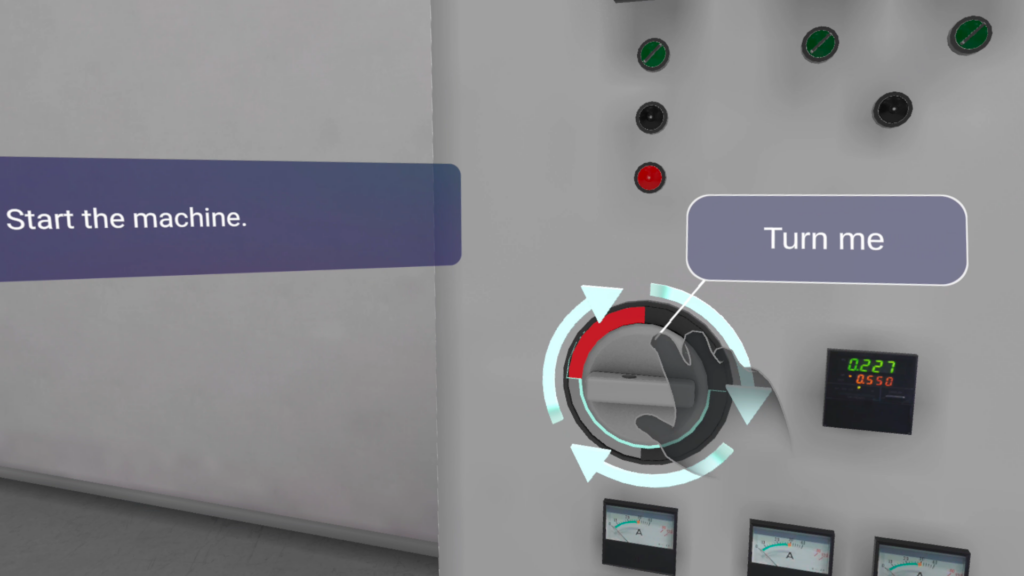

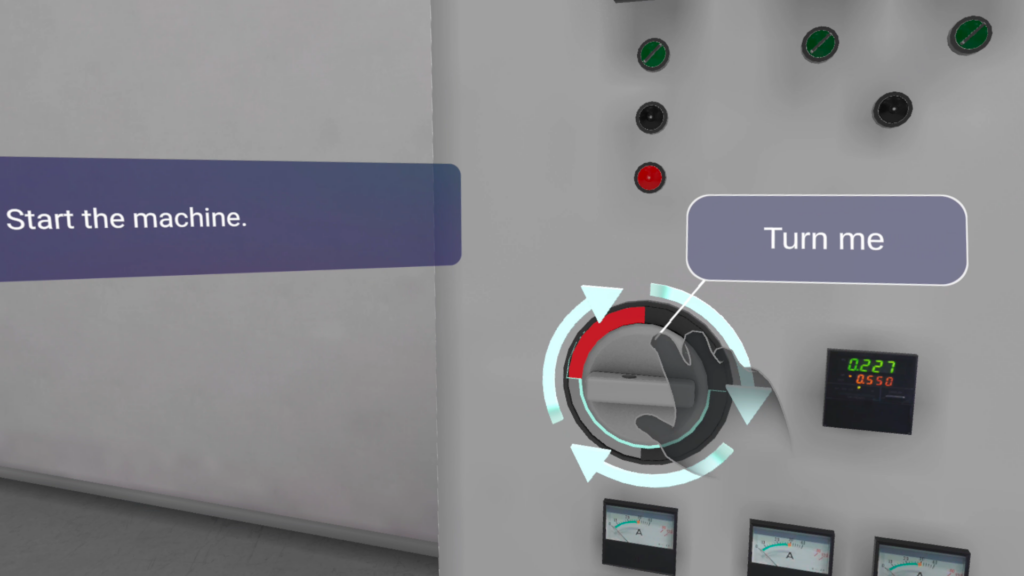

- Machine Operation Training

Trainees can navigate start-up, shutdown, and operation sequences for CNC machines, robotic arms, or conveyors. The system replicates machine interfaces, allowing users to familiarize themselves with control layouts, emergency stops, and adjustment settings. The outcome is fewer operational errors, faster onboarding, and minimized equipment wear. - Emergency Shutdown (ESD) Procedures

In a real emergency, seconds count. VR-based ESD training immerses workers in high-pressure scenarios such as steam leaks, electrical surges, or overheating presses. Trainees learn to follow lockout protocols, activate alarms, and coordinate with emergency response teams. Practicing under simulated stress builds confidence and reflex speed for true emergency response. - Confined Space Training

Workers develop familiarity with tight environments like tanks or maintenance chambers. The simulation replicates hazards like low oxygen levels and poor visibility, teaching proper procedures for entry, communication, and extraction. Repetition in VR prepares teams for safe coordination when executing real confined-space work. - Crane, Forklift, and Material Handling Operations

Operators learn to manoeuvre heavy loads, manage blind spots, and follow designated floor paths. The training emphasizes spatial awareness and balance control, helping reduce real-world collisions and product damage. Trainees can progress from basic control handling to complex warehouse logistics scenarios.

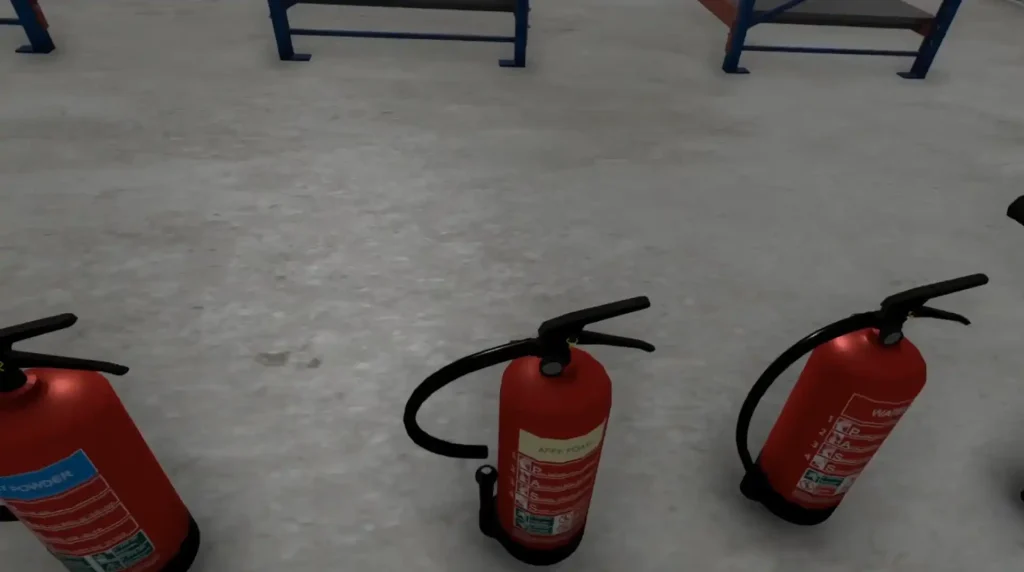

- Fire Safety and Explosion Response

Instead of static fire drills, immersive simulations confront learners with dynamic fires, explosions, and smoke conditions. The VR environment teaches early hazard recognition, proper use of extinguishers, and coordinated evacuation responses. It’s an effective way to reinforce fire prevention habits in a realistic yet safe space. Below is an example from a basic fire safety training demo we created that covers how different fire extinguishers work and which types of fires need which extinguisher.

Fire extinguishers lined up from our fire safety training demo

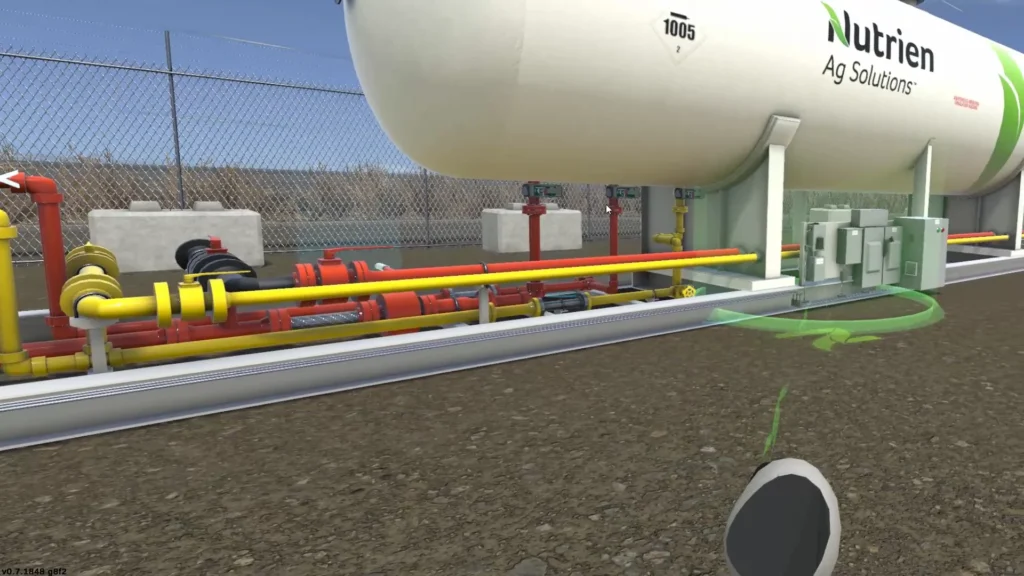

- Hazardous Chemical and Materials Handling

Chemical processing plants and labs can train workers on safe handling, labelling, storage, and spill response. VR demonstrates chain-of-reaction consequences, containment procedures, and appropriate personal protection steps. Employees witness the impact of improper behavior virtually, deepening understanding through visual feedback.

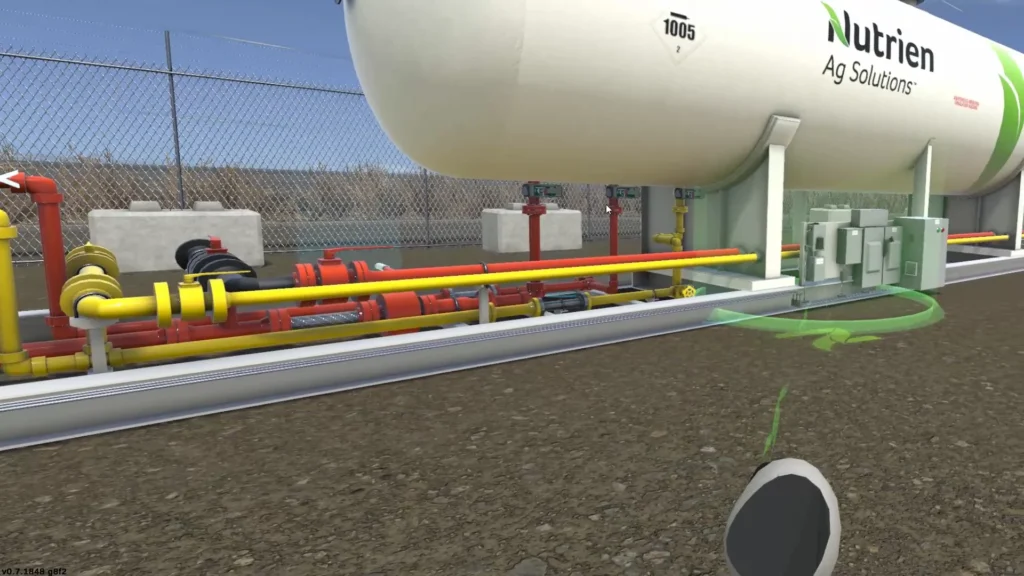

Nutrien Ag Solutions came to use for a VR Training solution that goes through the full process of an ammonia transfer and covers all safety criteria throughout the process, starting from site setup and ending at site closing after the transfer process is complete.

SHIIFT Hazardous Materials Ammonia Transfer Training VR

- Lockout Tagout (LOTO) for Energy Isolation

Improper energy isolation is a major cause of manufacturing accidents. VR enables step-by-step walkthroughs of LOTO procedures, allowing workers to see exactly where and how to secure electrical, mechanical, and hydraulic systems. Virtual simulations reinforce compliance and procedural discipline.

We created a VR lockout tagout training for the leading manufacturer of air conditioners, Daikin Global, which goes through the entire lockout-tagout-tryout procedure with hands-on tasks in for locking and tagging. This project was designed to be suitable for reselling to any company with some slight alterations to steps based on company requirements and changes to the machinery 3d models so we also created one for Kinross Gold.

- High-Voltage Electrical Equipment Training

Electricians and maintenance personnel can safely interact with virtual switchgear, transformers, and circuit panels. They practice diagnostics, voltage testing, grounding, and fault isolation without exposure to real current. Scenarios replicate arcing events to highlight the importance of distance and proper PPE. - Preventive Maintenance

Maintenance workers practice troubleshooting, lubrication, and part replacement on 3D replicas of actual equipment. The simulation guides them through inspection checklists and helps them identify early warning signs of failures. By reinforcing preventive care habits, plants reduce unplanned outages and improve asset longevity. - Personal Protective Equipment (PPE) Training

Workers learn the proper selection, inspection, and use of PPE across different zones of the facility. Interactive scenarios show the consequences of incorrect gear or neglect. This module promotes PPE compliance as a daily behavior rather than a mandate on paper. At SHIIFT, we almost always include a PPE training section in our VR training since this is one topic that is required in any sector and any procedure. You can see it here right at the start of our lockout tagout VR showcase video:

- Machine Guarding Awareness

VR visualizes common guarding gaps and unsafe adjustments, teaching workers how to spot and report them. Instead of examining static examples, trainees interactively assess equipment setups, identify risks, and apply corrective actions. This builds proactive safety observation skills. - Basic First Aid for Emergency Response

Rapid, informed response to an injury can save lives. VR training manufacturing solutions provide interactive simulations for treating cuts, burns, or crush injuries. It also reinforces emergency communication protocols like summoning medical teams or coordinating evacuation routes. - Slips, Trips, and Falls Prevention

Falls remain one of the most common industrial injuries. VR recreates cluttered floors, fluid leaks, uneven surfaces, and platform edges. Workers practice hazard identification and how to respond to the hazards spotted to help them reduce real-world incidents. - Ergonomics Training

Using motion-tracking input, trainees receive real-time feedback on posture, lifting mechanics, and workstation setup. They learn techniques to minimize repetitive strain injuries and strengthen overall performance. This is especially valuable for assembly, packaging, and logistics staff. Ergonomics training is incredibly important and with virtual reality, you can actually track the trainee’s exact body movements without needing to hire a specialist. - Risk Mitigation and Safety Awareness

This module combines multiple hazard types: mechanical, chemical, and procedural, so workers practice identifying risks in a time-pressured environment. It strengthens awareness, teamwork, and safety reporting culture through repeated exposure to realistic, problem-solving situations.

Across these use cases, the VR training benefits compound rapidly: fewer injuries, better retention, faster onboarding, and consistent safety culture across operations.

Final Recommendations

Manufacturers adopting VR should approach implementation in targeted phases, aligning training objectives with measurable performance outcomes.

- Start with high-risk operations such as machine operation, electrical maintenance, and chemical handling. Early success here establishes credibility and immediate value in safety metrics.

- Expand use to routine functions once core programs show results. Incorporating VR into material handling, PPE adherence, and ergonomics reinforces a culture of safety across all job categories.

- Maintain realism and plant alignment by using real CAD data and process layouts in VR scenes. Authenticity ensures transferability from simulation to on-site work.

- Track results with analytics. Measuring retention, task accuracy, time-to-competence, and incident reduction helps prove ROI and refine further modules.

- Blend VR with broader learning programs. Pairing virtual scenarios with mentorship or classroom review builds a complete training ecosystem that benefits varied learning styles.

Moving toward a VR-enhanced training system represents a significant technology upgrade and signals a strategic commitment to workforce resilience. Organizations that adopt immersive training routinely report measurable improvements: reduced injury rates, faster competency gains, and stronger retention of critical processes.

By converting traditional instruction into active, simulated experience, manufacturers not only protect their people but also prepare them to thrive in increasingly automated, high-stakes production environments. In the modern industrial world where precision and safety converge, virtual reality is becoming the new foundation for manufacturing training excellence.

As a final recommendation, if you’re working with a manufacturing company, you should get in touch with SHIIFT Training via the ‘Send a message’ link below to see how our VR training manufacturing solutions can become an asset for your company too.