Introduction to Virtual Reality for Oil and Gas Training

Training in the oil and gas industry has always demanded a balance between realism, safety, and cost. Workers often need hands-on practice with dangerous equipment, in environments that expose them to high pressure, toxic substances, explosive atmospheres, or heavy machinery.

Traditional training methods (whether classroom-based instruction or limited time in full-scale simulators) cannot fully replicate the stress and complexity of real-world operations. Worse still, practicing with actual equipment often creates downtime worth millions of dollars while also putting trainees at risk.

Virtual Reality (VR) has emerged as a transformative solution to these challenges. By placing workers inside immersive, highly realistic environments, VR allows learners to repeat critical tasks, master complex systems, and experience emergency scenarios without the associated hazards or costs. Unlike demonstrations or manuals, VR engages muscle memory, decision-making skills, and situational awareness training in a controlled and repeatable way, making it especially powerful for oil and gas training.

Below, we explore how VR is being applied across the industry, focusing on key use cases that address both everyday procedures and high-consequence emergency response.

8 Use Cases of Virtual Reality for Oil and Gas Training

To best explore how virtual reality can help with oil and gas training, we should first explore 8 actual use cases of VR training for oil and gas. For each use case, we’ll explain the existing situation in the real oil and gas world, and explore how we can use VR training simulators to replicate these scenarios that need training improvements to help you imagine how virtual reality actually upskills oil and gas employees within these real scenarios.

1. Training for Blowout Preventer (BOP) Operation

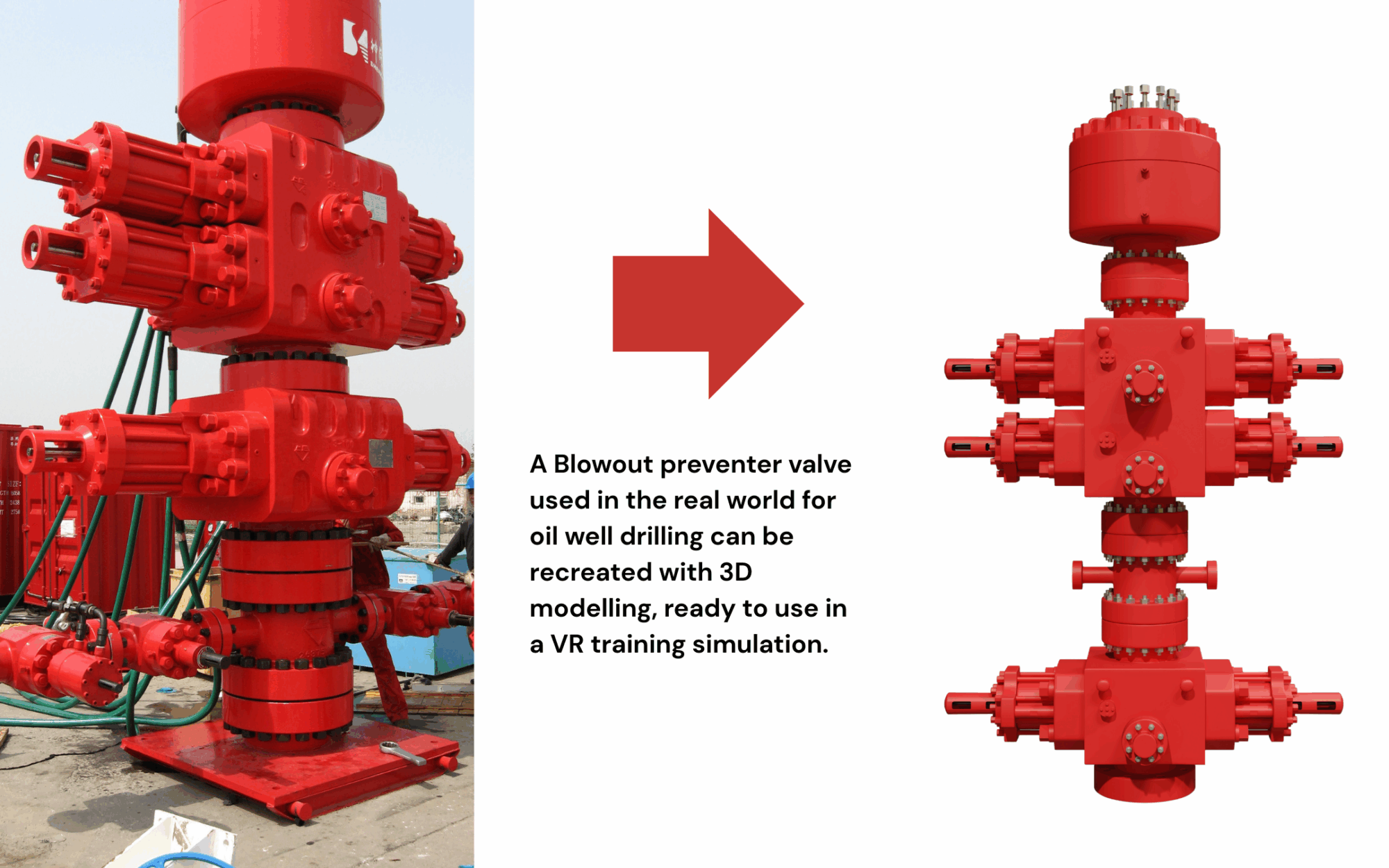

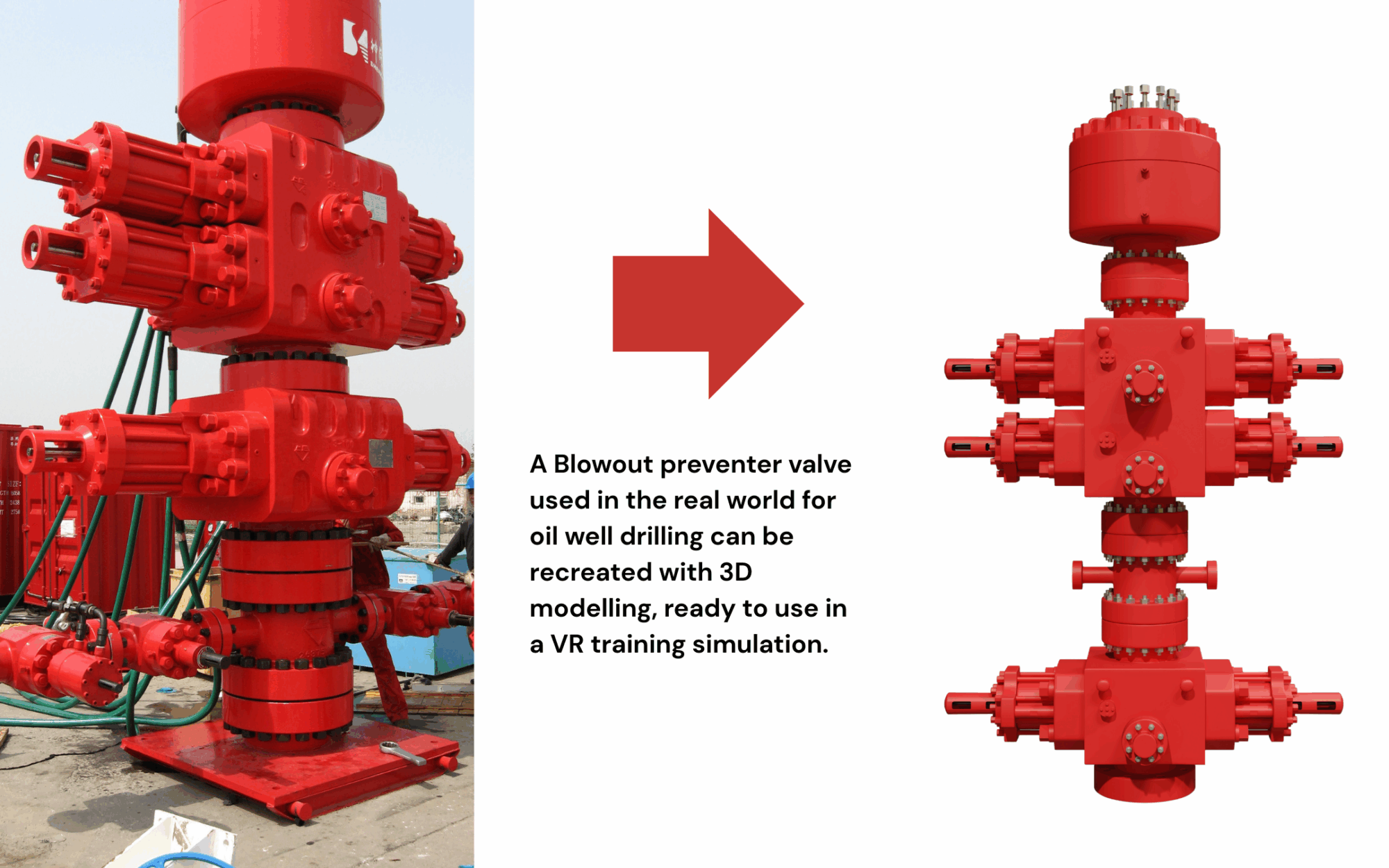

Blowout Preventers (BOPs) are among the most crucial pieces of safety equipment in drilling. They are designed to seal wells in the event of uncontrolled pressure surges, preventing catastrophic blowouts. Operating a BOP requires precision and calm decision-making under extreme stress.

Operators must activate the BOP to prevent uncontrolled well release (blowout). This requires quick decision-making, proper sequencing of valves, and familiarity with control systems.

Traditional training methods often involve classroom theory or limited supervised practice on test rigs. However, these cannot easily replicate the intensity of a real blowout.

With VR, operators can step into a virtual rig environment, learn the sequencing of correct valve activation, and experience different fault scenarios, such as partial system failures or delayed control response. By practicing under simulated stress conditions, operators develop muscle memory and confidence before ever facing a live well event.

- Safety instructors can recreate normal and emergency drilling scenarios at will, as long as the operator employee is wearing a VR headset, and trainees can practice activating the BOP, troubleshooting failures, and reacting under pressure.

- Trainees can experience failures or accidents while operating the virtual machinery, without experiencing any real consequences to cost or safety.

2. Emergency Shutdown (ESD) System Training

The Emergency Shutdown (ESD) system is the last line of defense against escalating failures, such as gas leaks, equipment malfunction, or fire. ESD procedures must be executed swiftly and flawlessly, yet most workers rarely encounter them in day-to-day operations. The process involves following shutdown sequences, isolating energy sources, and ensuring that the system returns to a safe state.

VR scenarios allow trainees to walk through the shutdown process step by step, making split-second decisions in real-time simulations. For example, a worker can practice recognizing alarms, isolating sections of a facility, or bringing a plant safely offline under pressure, without jeopardizing actual operations.

By repeating these exercises in a safe environment such as a VR training simulation, the oil and gas employees who rarely experience a real emergency can become confident and instinctively follow correct shutdown protocols when it matters most, without any panic.

- Oil and gas VR training simulator users can walk through the entire ESD sequence, including alarm response, control room actions, and manual intervention in the field.

- These emergency shutdown and other emergency response trainings would use digital twins of the specific oil and gas site the oil and gas worker is stationed, similar to the above image of the BOP being converted to 3D, an entire oil and gas site can be replicated to train on familiar equipment to dramatically reduce chances of anything going wrong in the real scenario.

3. Confined Space Entry Training

Tanks, vessels, and pipelines are vital components of oil and gas infrastructure but present serious hazards during entry. Workers face risks such as oxygen deficiency, toxic atmospheres, engulfment, or restricted exit routes. Confined space accidents are frequently fatal, often due to improper risk assessment or rescue delays.

In VR, trainees can complete the entire confined space entry workflow, from reviewing permits to atmospheric testing and communication protocols. They can also rehearse emergency rescues in which co-workers are incapacitated inside a vessel. These scenarios reinforce the importance of preparation while enabling teams to safely practice mistakes and learn from them, something not feasible in real-world spaces.

- Confined spaces come with many potential hazards, VR allows workers to visualize the each hazard in a first person perspective without dangers, much more powerful than a video.

- VR training in confined spaces can be used for multi-person or team-based training, confined spaces require communication between two workers and a VR training simulation gives them both an easy environment to practice together.

4. Crane Operations and Rigging Procedures

Crane operations, whether offshore on drilling rigs or onshore at refineries, are among the most hazardous activities in oil and gas. A single mistake in load rigging or signaling can cause dropped loads, equipment damage, or severe injuries.

VR environments can replicate crane cabins, rigging zones, and even weather conditions such as high winds. Trainees can practice load path planning, communicate using hand and radio signals, and experience the consequences of unsafe movements in a risk-free digital environment. The VR training reduces the likelihood of costly and dangerous accidents during live operations, while ensuring workers are familiar with both technical and teamwork protocols.

Crane systems are also a popular choice when it comes to physical rigs (replicas) to pair with virtual reality, giving oil and gas workers the same hands-on feeling they would have with a real crane as opposed to standard VR simulations that just use hand-tracking with grabbing the air, or controllers that vibrate to simulate physical touch.

An example of using physical controls by 3t Global

This crane simulation by 3t global demonstrates how physical controls can be used to enhance the VR training experience from an oil and gas perspective. Imagine this but instead of screens in a dark room, you instead wear a VR headset and have the true-to-life visual experience around you, and whenever you move the physical lever it controls the crane in your VR simulation. A perfect way for crane operators to have endless practice without zero harm to any assets/equipment or to employees.

5. Fire and Explosion Response

Perhaps no scenario instills more fear on an oil and gas site than a fire or explosion, particularly on offshore platforms or near wellheads. Response speed, evacuation order, and fire suppression effectiveness determine whether such events are contained or escalate catastrophically.

VR fire and explosion simulations allow workers to experience alarms, navigate muster points through smoke-filled environments, and use extinguishing systems in real-time scenarios. Teams can coordinate mass evacuations or practice specific roles like fire marshals and first responders. By rehearsing in VR, workers gain familiarity with routes, equipment, decision-making, and all skills critical in real emergencies where panic can easily take hold.

The below image is a clear example of how we use our 3D animation services to replicate oil and gas related sites and also be used for VR training (with less visual fidelity). Even though the example in the image was for a video, imagine how it could be used to train oil and gas teams by letting them experience panic-inducing scenarios like an emergency response.

They can practice going to muster points without fear, make correct decisions by rehearsing all the different scenarios where they are faced with a difficult decision during an emergency. With emergencies being quite rare, there aren’t many opportunities to build confidence and train for it in real life. Virtual reality solves this problem.

Left: Our 3D Replica of the One Guyana FPSO | Right: Real photo of the FPSO by SBM Offshore

6. Hazardous Chemical Handling

Oil and gas operations frequently involve hydrocarbons, corrosives, or toxic chemicals that can pose health hazards if mishandled. Training workers for chemical spills, leaks, or exposure events in live environments is rarely feasible.

VR makes it possible to simulate realistic spill scenarios, where trainees must don appropriate Personal Protective Equipment (PPE), establish containment, and apply emergency response protocols. By repeatedly practicing these steps, workers gain confidence in their ability to respond quickly and effectively. Unlike textbook learning, VR embeds critical procedures into memory by allowing workers to experience them under simulated urgency.

Check out our VR training for chemical handling of ammonia for Nutrien Ag Solutions, this project wasn’t for the oil and gas sector, but it’s still a great example and the video can help you visualize how it can be used for oil and gas training.

7. Lockout Tagout (LOTO) for Energy Isolation

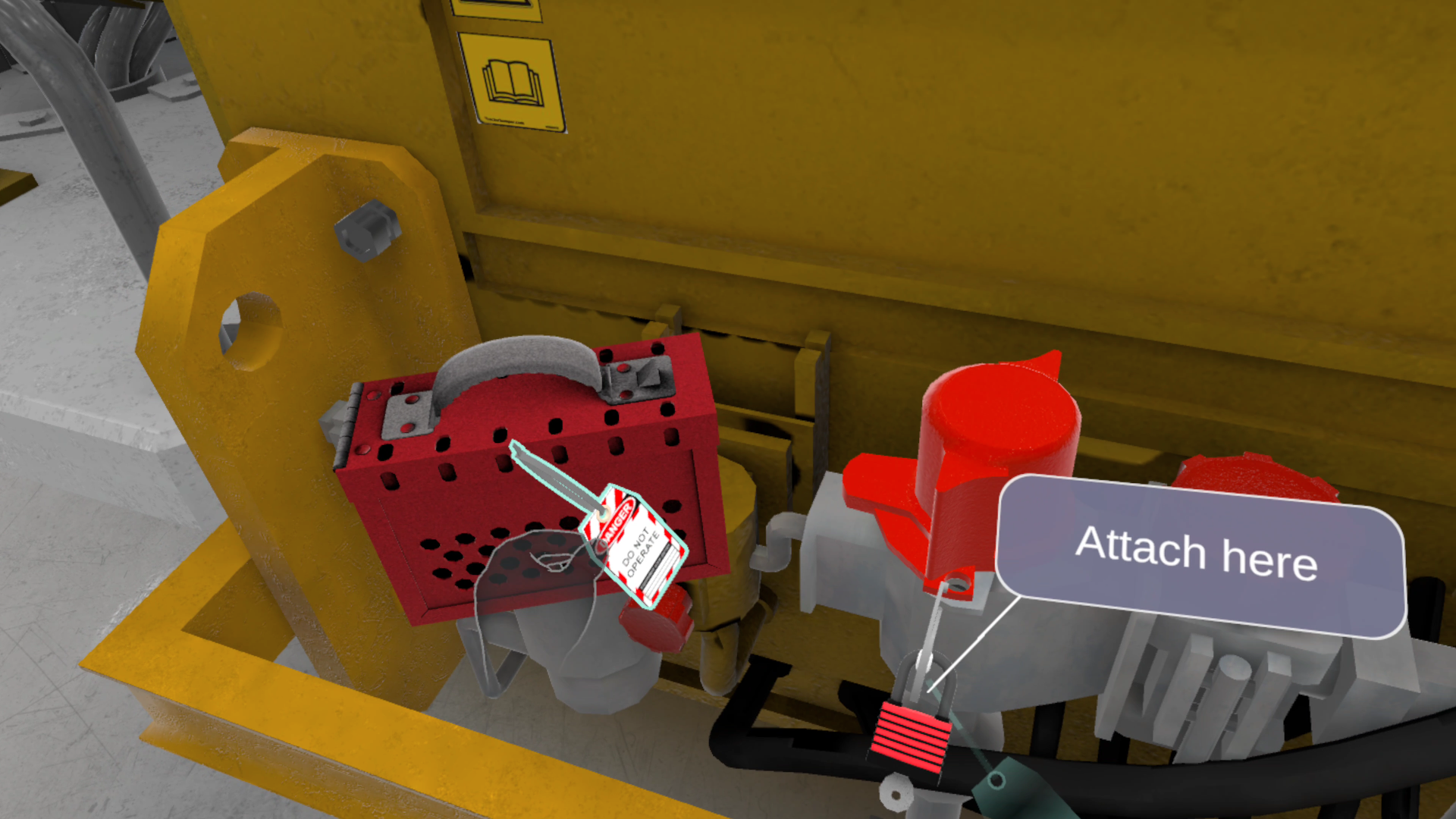

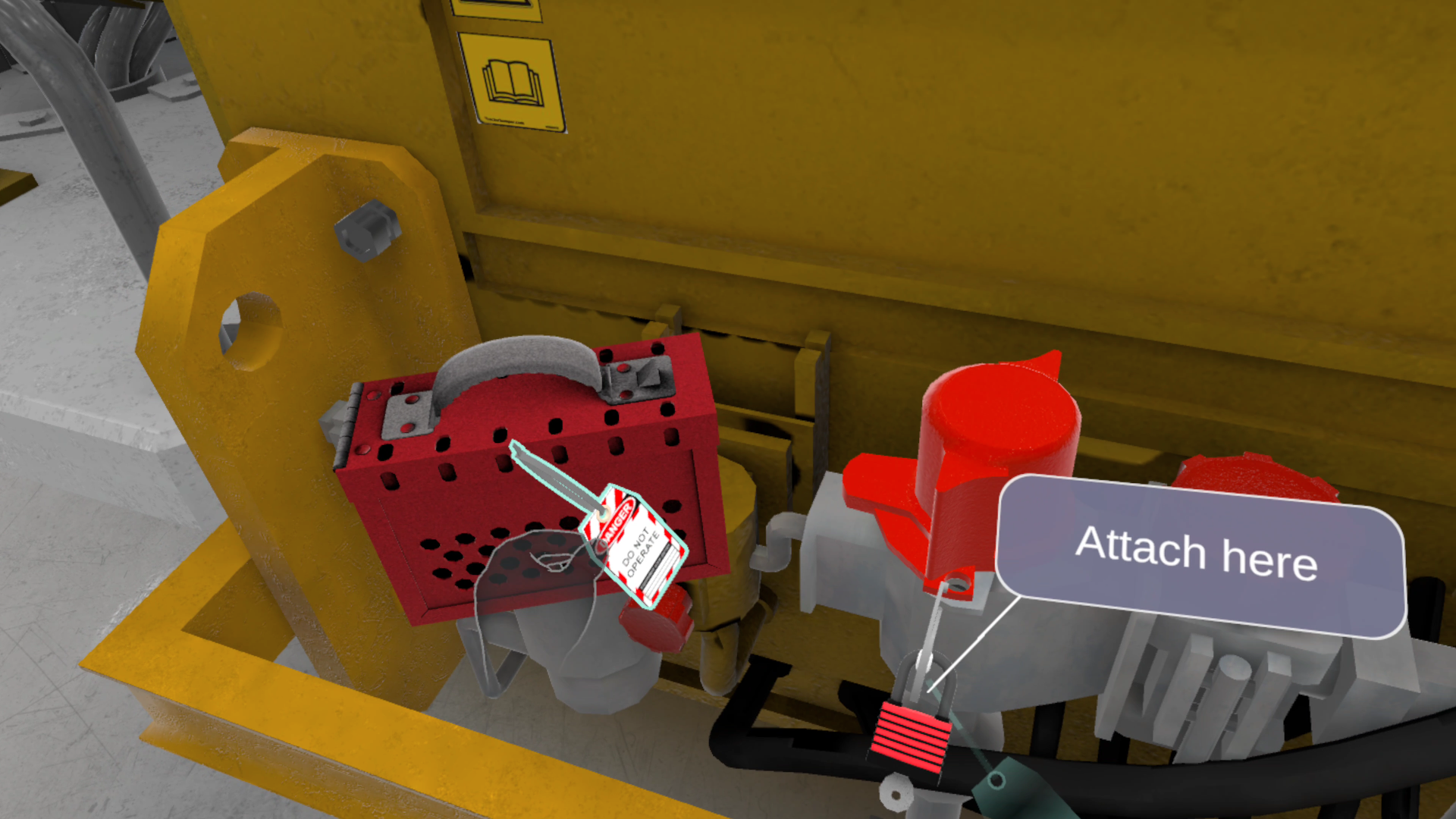

Lockout Tagout (LOTO) procedures are essential for ensuring worker safety during equipment maintenance. Given the variety of energy sources, electrical, hydraulic, pneumatic, thermal, the process can be complex and prone to missteps.

VR training enables workers to practice isolating multiple energy sources, applying locks and tags, and verifying isolation before entering a hazardous area. Virtual practice prevents complacency, reinforces compliance, and teaches workers to spot potential shortcuts or errors that could lead to serious injury. Rehearsing these methods digitally also saves facilities the cost and downtime required to replicate such training in real-world plants.

SHIIFT created a VR training for lockout tagout, that can be used to practice electrical isolation across multiple sectors like manufacturing, mining or oil and gas.

8. High-Voltage Electrical Equipment Training

Switchgear, transformers, and high-voltage installations involve deadly risks, especially during inspection or maintenance. Human error in this domain has severe consequences, including arc flash accidents and fatalities.

VR training places workers in a safe digital environment where they can practice approaches to energized equipment, follow PPE protocols, and complete maintenance sequences without risk. For example, they can virtually apply grounding clamps, verify the absence of voltage, and rehearse safe work zones. This approach not only reinforces safety standards but also reduces reliance on costly full-scale electrical training rigs.

- Technicians can practice working with high-voltage switchgear and transformers in a fully simulated oil and gas environment while wearing a VR headset, allowing them to rehearse inspections, breaker racking, and routine operational procedures safely.

- Trainees can experience scenarios such as an unexpected arc or short circuit in VR, allowing them to practice monitoring system indicators, identifying abnormal readings, executing correct operational adjustments, and coordinating with colleagues, all without risking equipment, downtime, or personal injury.

Final Recommendations

The oil and gas industry faces unrelenting challenges in equipping its workforce with the knowledge and confidence to perform safely in high-stakes environments. Traditional training approaches, while effective to a point, cannot replicate the intensity or variety of real-world hazards without enormous expense and risk.

For oil and gas companies looking to strengthen training programs, VR offers a practical and scalable way to address both routine procedures and high-risk emergencies. To get the most value from VR training at an oil and gas site:

- Start with high-consequence tasks. Focus first on procedures where mistakes carry the greatest risk, such as BOP operation, ESD, and confined space entry. Teach life-saving rules and the consequences of ignoring them in immersive scenarios that feel real.

- Include everyday processes. Extend VR training to routine but critical activities like lockout tagout, crane operations, and chemical handling to build safer habits. These are the sort of tasks that users can easily develop a mindset of ‘I’ve done it hundreds of times’ and go to autopilot, but unlike real-life, VR will call you out on every mistake you make even if it doesn’t always result in an accident.

- Keep scenarios realistic. Ensure environments, equipment, and procedures match actual site conditions so the training translates directly to the job. Base your virtual site on your real site, and match the VR scenarios with situations you would actually expect in oil and gas.

- Measure outcomes. Track improvements in competency, error reduction, and incident rates to demonstrate ROI and refine training modules.

By approaching VR training strategically, oil and gas companies can reduce incidents massively. If you’re interested in learning how oil and gas companies are using VR training right now, read our article on how VR training is affecting the energy sector in 2025.

If you’re already sold on the idea of VR training for oil and gas, your next best step is getting in touch and organizing a discovery call with us and joining our other clients levelling up their training with virtual reality!

Send us a message with the link below.